Add to Cart

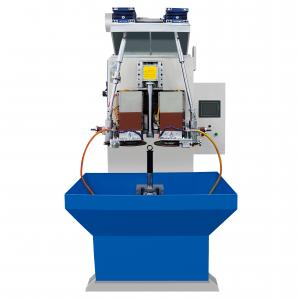

HWASHI Repair Shock Absorber Rolling Seam Welder/Welding Machine

DESCRIPTION

The seam (roll) welding special machine is the evolution of spot welder. It uses the roller electrode to replace the cylindrical electrode of spot welding and as the welding work piece moves between the rolling plates, the seal welding will generate weld nuggets which will overlap with each other so as to achieve welding effect. AC pulse current or amplitude modulation current will be adopted, but three-phase medium frequency DC are also available.

| Intelligent welding control system

| High quality super hard copper alloy welding wheel Made of excellent material processing, not afraid of high temperature, not afraid of wear and tear, good electrical conductivity. | Shape structure and welding method

|

| Welding Method of The Seam Welding Machine Adopt standardized welding electrode. Special electrode molds and welding methods can also be customized according to the product specification. |

SPECIFICATION

| Model | WL-FS-75K |

| Input Voltage | 380V±10% 50Hz |

| Rated Capacity | 75KVA |

| Rated Duty Cycle Rate | 25% |

| Max Secondary Floating Voltage | 9.5VAC |

| Max Secondary Short Circuit Current | 38000A |

| Welding Transformer Insulation Grade | Grade F |

|

Controller Program Segment | Prepressing, Preheating, Cooling, Welding (Forge And Press), Cooling, Tempering, Maintaining, Stop; The Heat Of Preheating, Welding And Tempering Could Be Adjustable Respectively. |

| Program Segment Time Adjustment Range | 0~99 Cycle, No Error |

| Controller Heat Adjustment Range

| 15%~99% |

| Compensation For Power Grid Voltage Fluctuation | When the value of power grid voltage fluctuates within the range of ±10 %, the secondary voltage fluctuates within the range of ≤±3 % |

| Electrode Pressure | 9kN(I),1.8kN(II) |

| Gas Consumption | 5m3/h |

| Cooling Water Consumption | 200L/H |

| Welding Wheel Diameter | 200-250mm |

| Welding Wheel Width | 5mm |

| Welding Wheel Rotate Speed | 800-4000mm/min (adjustable) |

| Welding Wheel Throat Depth Distance | 300mm |

APPLICATION

This machine is widely applied to welding motorcycle shock absorber, damper and bumper, etc.

FEATURE

1. This machine is of reasonable design, beautiful appearance, stable welding performance.

2. It adopts intelligent micro-computer controller which can set different kinds of welding specification. Multi-segment electrification method has the functions of soft start welding and ending welding.It adopts subprime constant current feedback control mode which will do auto compensation when the voltage is unsteady in order to ensure the stable welding current.

3. It adopts high power welding transformer with all-round water cooling, which can complete different kinds of product’s welding efficiently to guarantee welding quality.

4. This welding machine is widely applied to various kinds of stainless steel products and it can achieve multifunction usage.

Welding sample and effect